Tel:+86 199 3712 3680

Tel:+86 199 3712 3680

Tel:+86 199 3712 3680

E-mail:info@zxmetalmesh.com

Address: Zhengdong New District, Zhengzhou City, Henan Province, China

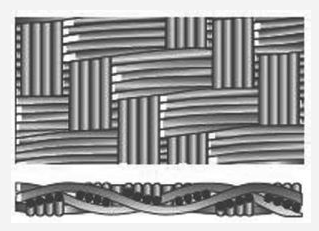

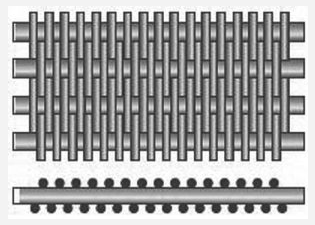

Woven wire mesh is woven to size in the same way cloth is woven on a loom.

Descriptions:

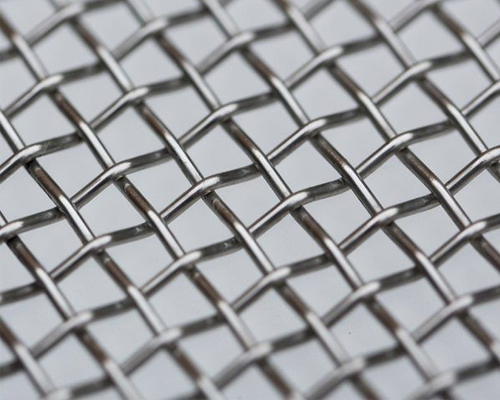

Woven wire mesh, also known as wire cloth, is amazingly versatile and easily adapted to almost any application. Our main industrial woven mesh stock material is stainless steel types 304 and 316 in apertures from 50mm to 40 micron in normal weaves to as fine as 15 micron particle retention in Dutch weaves. We stock a range of standard meshes in other materials such as copper, brass, nylon and galvanized mild steel. Heavy duty screens made from stainless steel, galvanized mild steel and high carbon mild steel are generally manufactured to order.

Material:

Carbon steel, Galvanized steel, Stainless wire mesh, Aluminum, Copper, Brass

Features of Woven Wire Mesh:

Solid construction

Extremely versatile

Easy to install

Can have low resistance to wind loads

Easily cut to fit

Available in many materials, such as stainless steel and aluminum

Applications:

Woven wire mesh baskets

Woven wire mesh architectural grilles

Woven wire mesh display shelves and stands

Woven wire mesh racks

Woven wire mesh liquid filtration

Woven wire mesh air filtration

Woven wire mesh wall reinforcement

Woven wire mesh handrail panel inserts

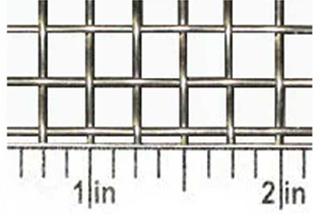

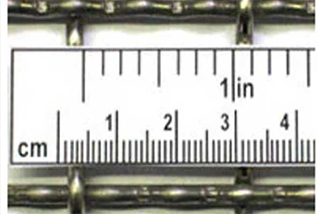

Mesh Count:

International standards identify mesh count or mesh number by the number of openings per linear inch. For example 4 mesh indicates that there are four openings in a linear inch.

Apertures are the clear opening between two parallel wires and wire diameter is the thickness of the wire or wires in both directions.

Aperture in mm

Wire Diameter in mm

WOVEN WIRE WEAVE STYLES

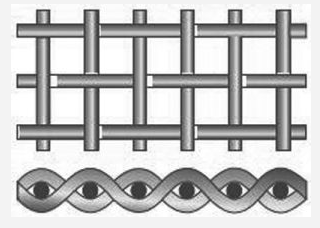

Plain Square Woven Wire

The most common wire weave, with the same diameter warp and shute wires, woven in a simple over and under pattern. This style produces screens with the same mesh count in both directions.

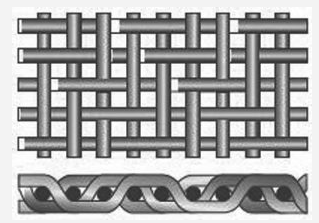

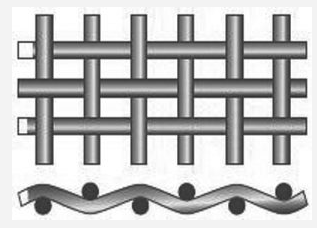

Twill Square Woven Wire

Each shute wire typically passes over two warp wires and under two producing square openings. Twill weave can be made from larger-diameter wires than would be possible in plain square weave, to obtain greater strength, density, or corrosion resistance.

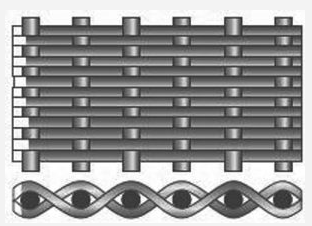

Plain Dutch Woven Wire

This weave style is woven in a plain, over and under pattern. The plain dutch woven wire style is a very tight weave because a thinner, smaller diameter shute wire is used. Dutch weaves do not have a straight-through, clear opening like most plain weave styles. Instead, the weave style creates a tortuous path through which very fine filtration and particle retention can be achieved. Dutch weaves may be specified by a “mesh count” or an “absolute filter rating.”

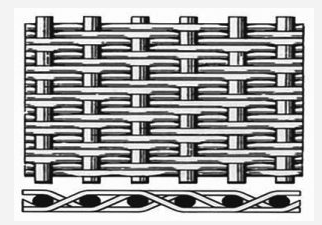

Dutch Twill Weave Wire

This weave style is similar to Plain Dutch, except it is woven in Twill style. Each wire passes over two wires then under two wires, still utilizing a smaller-diameter shute wire, allowing an even tighter weave and even finer filtration than the Plain Dutch weave.

Reverse Dutch Weave Wire

This weave style is the same weave as Plain Dutch, except the warp and shute wires are reversed. The larger shute wires are woven closer together than would usually be seen in a Plain Dutch weave.

Rectangular or “Off-Count” Weave Wire

This is a Plain weave wire cloth, woven in an over and under pattern with a different number of wires in the warp and shute direction, which yields a rectangular opening wire cloth. Rectangular openings are often used in sifting and sizing operations to increase product “through” capacity, with minor sacrifices in accuracy. To reduce material costs, off-count wire mesh may be substituted for square wire mesh in some applications that do not require a high level of accuracy. Some wire cloth vendors will substitute off-count wire cloth when certifications are not specified by the manufacturer. For example, a 90 x 100 mesh may be substituted for 100 x 100.

Stranded Weave Wire

Usually woven in the Plain Square style, each warp and shute “wire” is composed of a “bunch” or “group” of small-diameter wires, which are woven into a finished product.